News

Face Mask Making Machine: What Are They And How Do They Work?

Jul 22, 2020

It is said that the mask bandage is the key part of the mask, so the mask bandage machine is also very important. But what is a mask bandage machine and how does it work? In this article, we will find the answer to this question. This article will also introduce the role of masks in the current epidemic situation and the recent changes in the epidemic situation. We will also analyze the working principle of the mask binding machine and the characteristics of the mask binding machine used in the mask production. This paper will also study the important accessories of mask bandage machine.

If you are a mask supplier, or a researcher in a medical mechanical institution, please read through. The information contained here is designed to give you a better understanding of this important part of making masks.

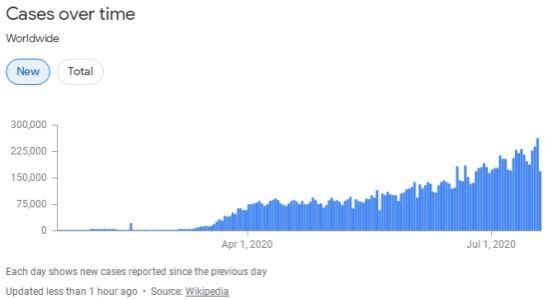

Let’s look at the current epidemic.

Experts on the function of the mask certification

A range of new research on face coverings shows that the risk of infection to the wearer decreases by 65%, says Dean Blumberg, chief of pediatric infectious diseases at the University of California, Davis Children’s Hospital.

Blumberg and Ristenpart repeatedly made the point that research continues to support the fundamental methods to prevent spreading COVID-19: Wear masks, maintain social distance, and keep social interactions outdoors whenever possible.

The product configuration of mask binding machine

Product Brief

A body machine. After the mask body is output by the body machine, the mask semi-finished products can be processed into finished products by spot welding machine. This machine adopts PLC, touch screen control, single-phase motor for main conveyor belt, stepping motor for turning, accurate transmission, stable control and adjustable speed. Aluminum alloy frame, lighter and stronger. High stability. Fully automatic. Once the non-woven material in the unwinding part is exhausted, the machine will stop automatically.

Working principle

This machine creatively combines the cup mask edge melting and punching cutting two independent processes, multi station turntable, welding with cutting device, welding and cutting at the same time, using PLC control system, touch screen settings, simple and convenient operation, can be used by a single person, only need workers to release and take materials, which can greatly save labor Automatic production, can use 1 ~ 4 layers of PP spunbonded non-woven fabric activated carbon and filter materials, the whole machine from raw material feeding to nose line insertion, edge sealing, cutting finished products are all one line automatic operation, according to the different raw materials used, it can reach different standards such as N95, FFP2, etc. The flat mask production equipment has stable performance, high output, low defect rate and easy operation.

Machine features

Folding automatic feeding system

1. Aluminum alloy frame, solid and beautiful, to ensure the size of the finished product is accurate;

2. Stainless steel fixture, adjustable from left to right;

3. The tension wheel is set to adjust the fabric tension, so as to effectively ensure the beauty and smoothness of the finished product;

4. Independent nasal line conveying group, convenient for adjustment and maintenance.

Folding and folding forming system

1. Insert folding device, easy to adjust and adjust

2. Large diameter welding wheel can effectively reduce product deformation.

Folding ultrasonic heat sealing system

1. Titanium alloy mould

When most mask machinery manufacturers use aluminum alloy, Lijin mask machine has provided and actively advocates customers to use titanium alloy mold. Compared with aluminum alloy, which is easy to oxidize and burst, is not suitable for long-term rush operation and short service life, titanium alloy has obvious advantages: A. good toughness, suitable for long-term vibration; 2;

B. The thermal / ultrasonic conductivity is strong, so as to ensure the beautiful welding and cutting effect of the product;

C. High hardness, not easy to crack, deformation and rust;

D. Although the cost of titanium alloy is about ten times higher than that of aluminum alloy, titanium alloy die is obviously better than aluminum alloy in terms of overall production benefit. 2. Imported ultrasonic transducer, 20K international frequency standard, output more powerful and stable; plus two sets of ultrasonic system, effectively ensure the welding quality of products.

3. PLC program controls the action of the whole machine to reduce the operation difficulty of users.

Folding discharge system

1. Forming two pieces of products at one time to improve the production speed

2. Product discharge position, automatic stacking, convenient for finishing and stacking of finished products, saving time and labor for ear band welding in the next process.

3. The whole machine has stable performance, continuously adjustable production speed, high production efficiency, up to 160 pieces per minute, convenient and accurate counting, high utilization rate of raw materials, simple and convenient operation and adjustment, high degree of automation, and effective reduction of labor cost.

List of important accessories

No. | Item | Brand |

1 | Cylinder | Air TAC |

2 | Guide screw | Air TAC |

3 | servo motor | Mitsubishi |

4 | PLC pic | Mitsubishi |

5 | Bearing | NSK/Japan、Samick/ Korea |

6 | track | CPC |

7 | Optical fiber amplifier | Keyence |

8 | touch screen | Weiview / Kuntai |

9 | Photoelectric induction | Omaron / Idec |

10 | Button | Bifamilies |

11 | ultrasonic | Mitsubishi |

Previous:HOW EARLY DID IT START?/Next:Talk About: Choose The Mask Machine You Should Know The Following Points

Related News

Latest Date On Novel Coronavirus

HOW EARLY DID IT START?

Talk About: Choose The Mask Machine You Should …

Full Automated Tie On Surgical Dust Mask Bandag…

Mask-wearing Plays Big In Europe’s Post-lockdow…

Trump Tweets Image Of Himself Wearing A Mask An…

The Features And Functions Of Mask Binding Mach…

Face Mask Making Machine: What Are They And How…

What Are The Characteristics Of Non-woven Bag M…

Types Of Wear And The Role Of Lubricants

Related Products

Our Service

Q1:Are you manufacturer or trading company?

A1: We are manufacturer with own factory and exporting department.

Q2: What’s the lead time of your machine?

A2: Normally it’s about 30~45 working days.

Q3: What’s the payment terms?

A3: 30% deposit TT, 70% paid before shipment; or L/C, Western Union.

Q4: Can we check machine before order?

A4: Yes, welcome to visit our factory and check machine anytime.

Q5:what type of mask machine we produce?

A5:Flat mask machine(1+1、1+2、1+3),Folding mask making machine(N95),Fish type mask making machine,single earloop welding machine and so on.

Q6: Does the machine power voltage meet buyers’ factory power source?

A6: We can do it as your request.

Sanlin Machinery Co., Ltd

Zhoutian Village,Xincheng Street,Ruian City,Wenzhou,Zhejiang,China

Ph:+8618966272131

Tel: +86-577-66803111

E-mail:sales@sanlinmach.com

QR Code